The latest in pressurized Green Houses

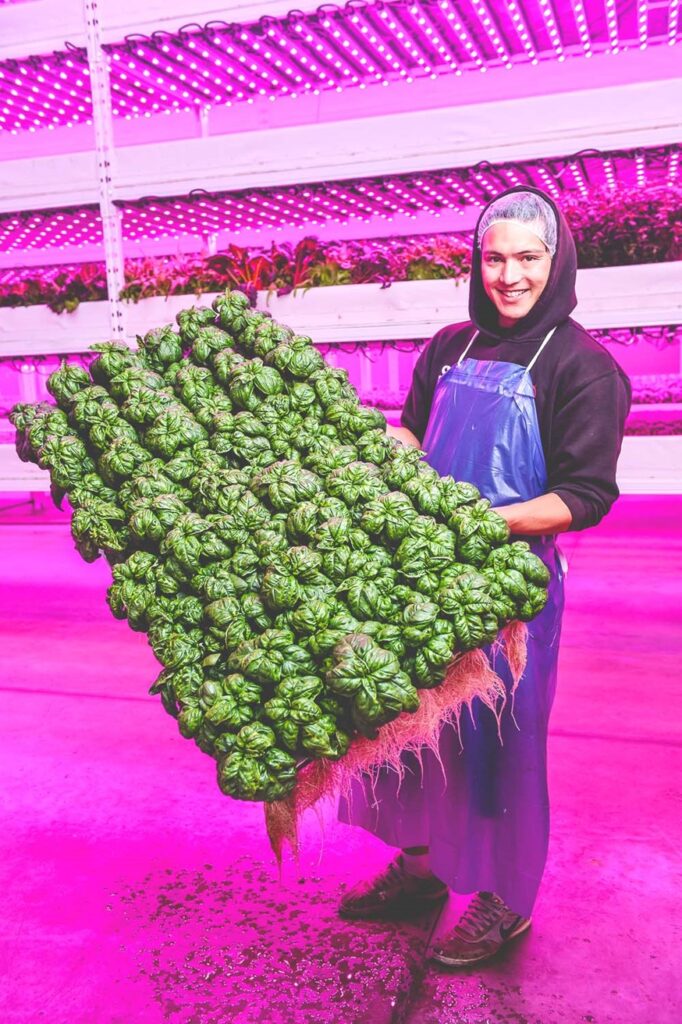

Less water consumption. Hydroponic harvest technic reduces water consumption levels due to water is re-used when purifying systems are added. They produce more product nutrition. Hydroponic harvest technical can produce 80% more product nutrition than traditional ones, Plants grow faster. They grow 30% faster in comparison with other harvest methods. Temperature and humidity can be totally controlled. Complete environment control within the greenhouse. Installation in any place due to the harvest is deployed on water,. Within the greenhouse, soil quality has no impact.

•Plant harvest in water

•Feed the plant directly with the exact nutrient quantities through a watery solution.

•Simple, clean and low cost model.

•Quick growth and rich in nutritive components vegetables are produced.

•It is convenient when soils with agricultural ability are not available

•Nutrients are re-used.

•

•It is more clean. Herbicides are not needed.

•

•Harvest at any time. Climate, location, place neither season of the year, have not impact using hidroponic technic harvest.

•High quality products. Due to cleanship, nutrients use and no dangerous chemical products use, heathy and high quality food is produced.

•Modular greenhouses. Harvest is modular, more surface can be added as demanded.

•

Profitable harvest. It is producing all the year 3-4 crops

•Decrease environment impact.

Lettuce soil-less harvest

Red fruits soil-less with led lighting harvest

Inner with led lighting soil-less harvest

Located at height with led lighting soil-less harvest

Indoor with led lighting soil-less harvest

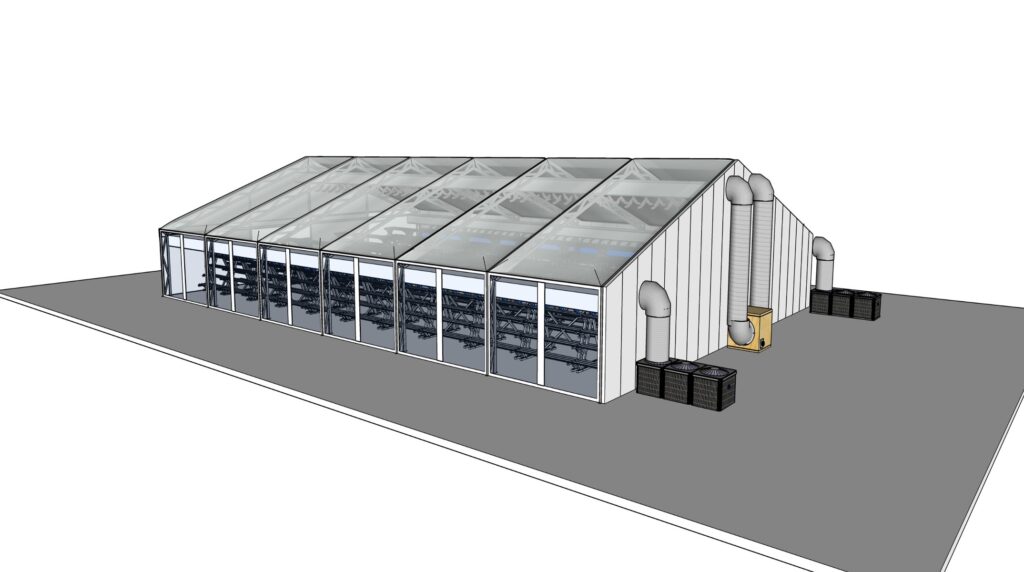

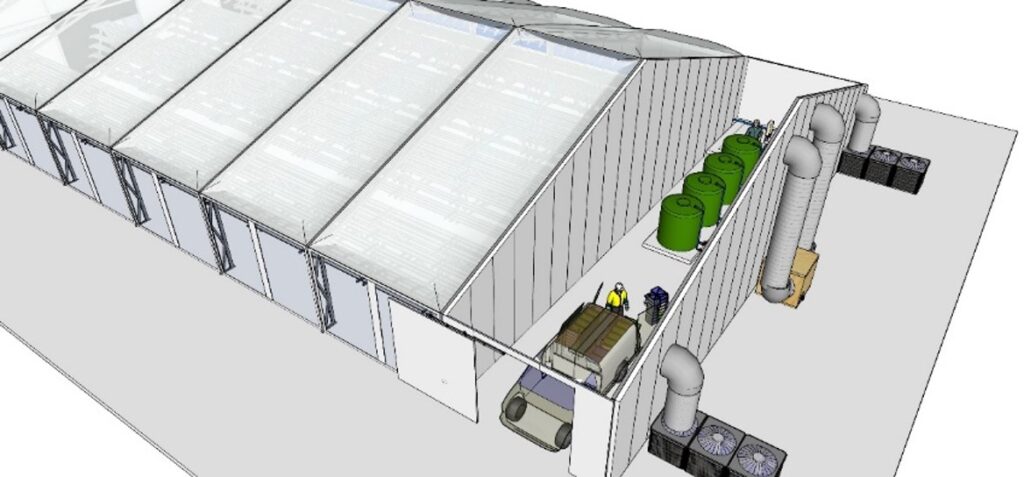

1. Pressurized structure Climate control

2. Harvest system able to multiply by 5 the harvest surface

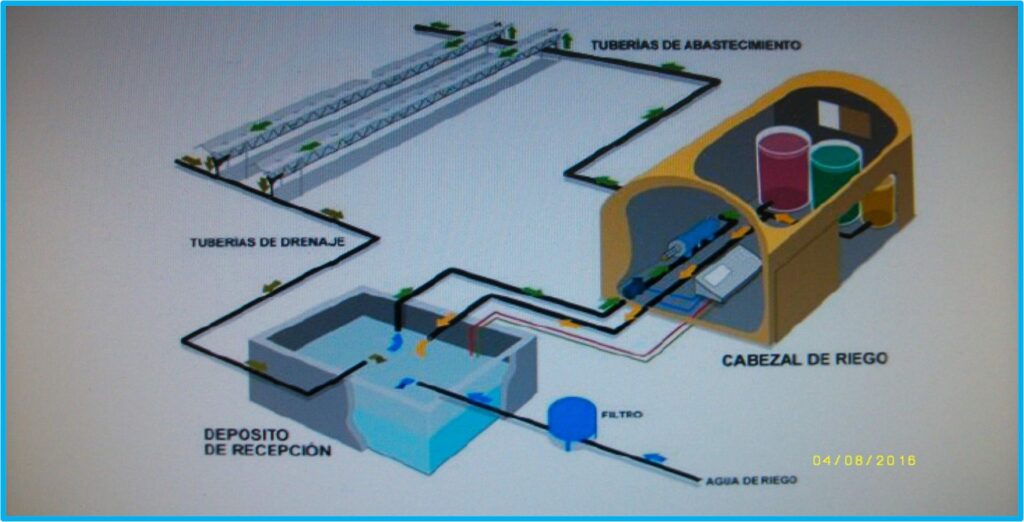

3. Fertigation circuit design, development and control even remotely

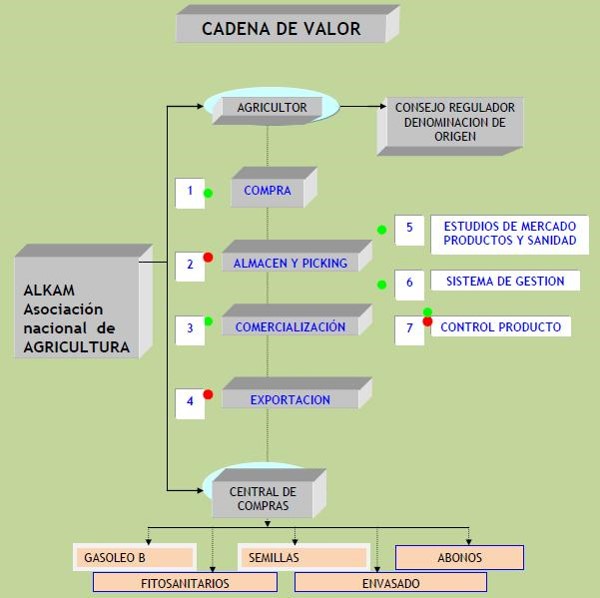

4. Procurement centralization and commercialization

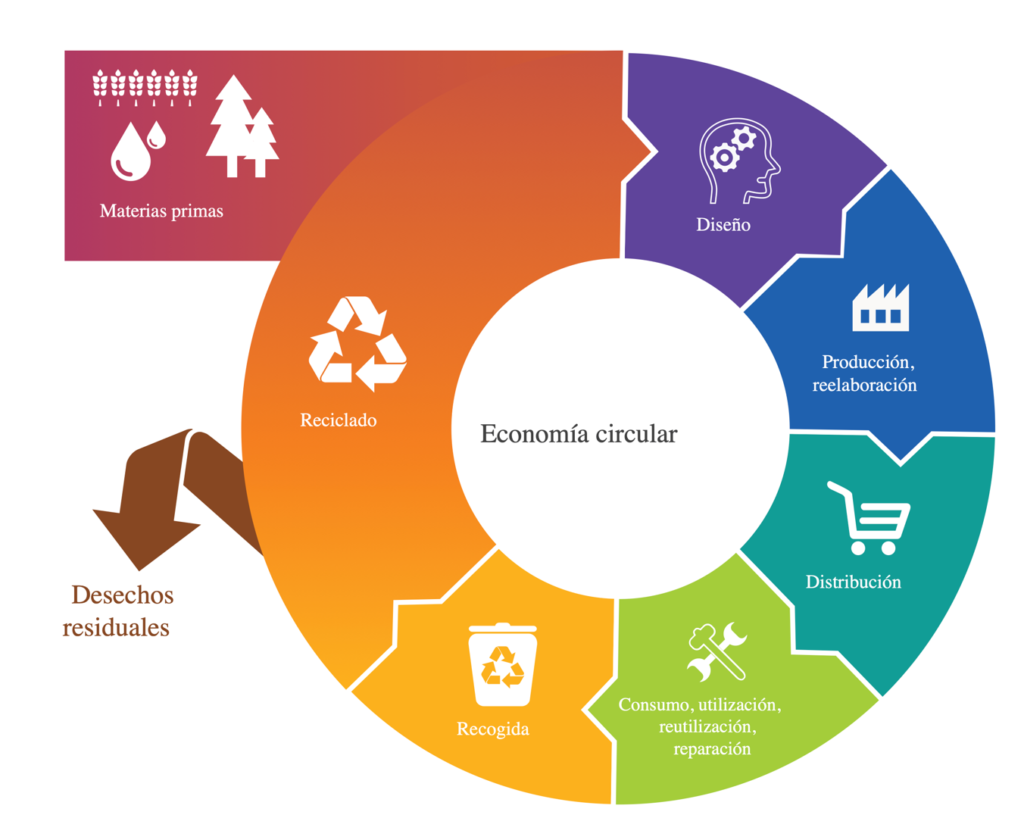

5. Round Economy for the area.

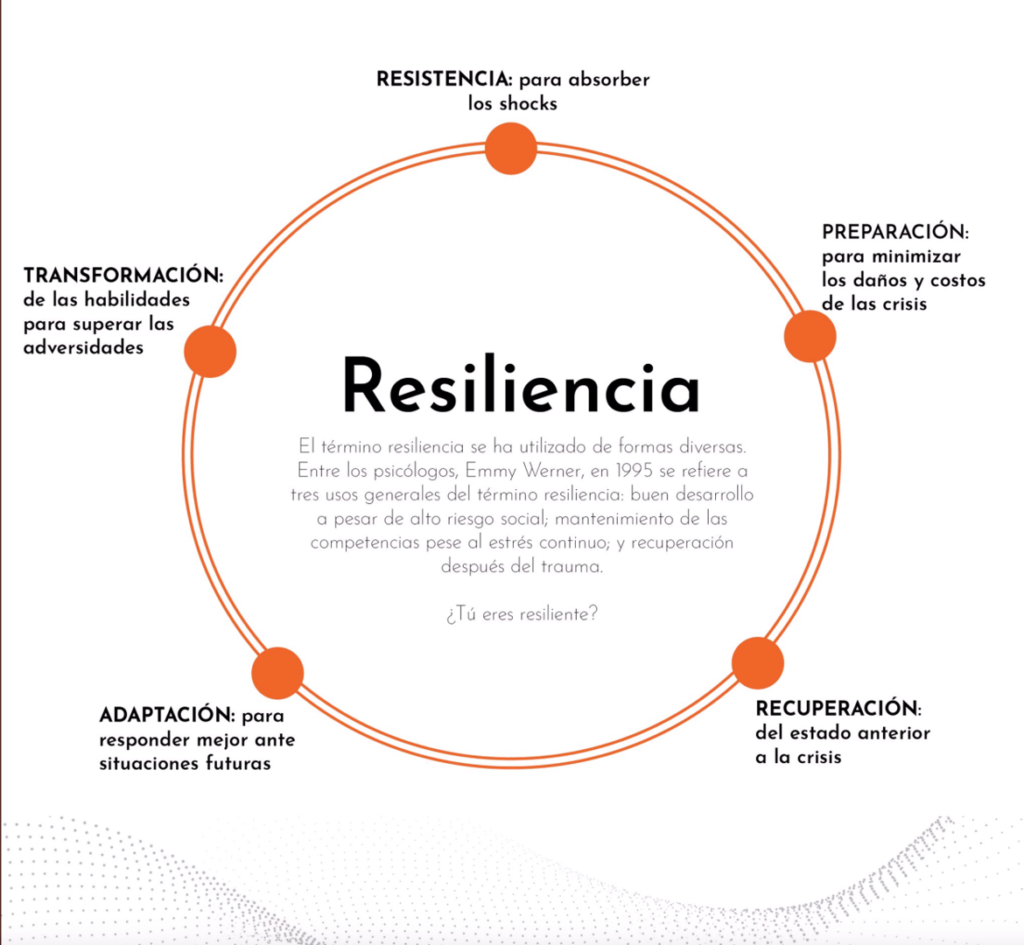

6. Economy strength of the Community reinforcing its identity

When is appropriate to use a pressurized structure?

- When energy cost is high

- When to keep stable temperature variations at lowest cost is needed

- When water is a scarce resource and unevenly distributed

- When the aim is to build a protected environment against rough atmospheric conditions When the aim is to avoid plagues and to protect the crops

- §Higher efficiency for parameters management such as temperature, humidity, CO2 concentration, absolutely, the climate we need in our greenhouse

- §Maximum useful livelihood for PVC structures and membranes

- §Maximum resistance of the canvas against snow and wind loads

- §Long open layout without column areas, which improves available soil optimization

- §The greenhouse can expand by modules according need increase.

- §Short assembly timing

- §Side high availalbe until 12 metres, deployed in one or more floors

Strawberry harvest deployed in double cascade

Model TOP H

- Patented benchs increase on substrate harvest length. Pending on harvest type, can be up to 6-7 times

- Structures homologated according to rules related to materials in contact with food

- Maximum resistance for plant and substrate loads

- Structures deployed by modules

- Short assembly timing

- The solution located at height facilitates the crop collection job

- No maintenance cost